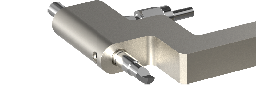

Sharp cutting edges, small corner radii and ground chip grooves guarantee optimum cutting behaviour. Sharp cutting edges made of wear-resistant and at the same time tough carbide grades are available in coated and uncoated versions for machining all common materials, even those that are difficult to machine. The SDA toolholder made of highly tempered steel can be installed in commercially available clamping devices. The cutting edges are changed manually and usually do not require remeasurement of the axial and radial position.

Roberto NICOLI

Roberto NICOLI