Advantages:

-

Thread depth corresponds to drilling depth for thread milling

-

Lower torque than for tapping and forming

-

Short milling chips avoid chip problems

-

High Speed Cutting (HSC) possible

-

Process-safe with long service life

-

Long service life due to improved geometry

-

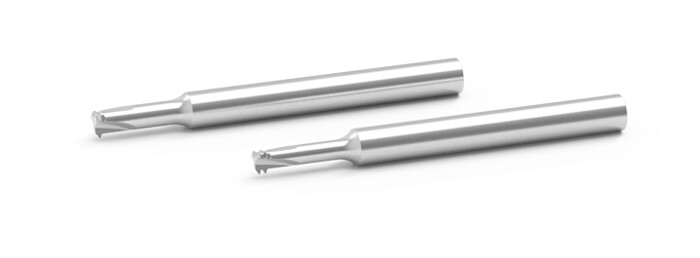

More feed due to high number of teeth

The following conditions require the use of a tool with only one row of teeth:

-

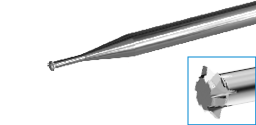

In a blind hole there is too little space at the bottom of the hole.

-

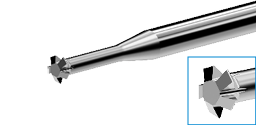

The cutting pressure with a tool with two rows of teeth is too great.

-

If the tool is also used for deviating slopes.

Roberto NICOLI

Roberto NICOLI