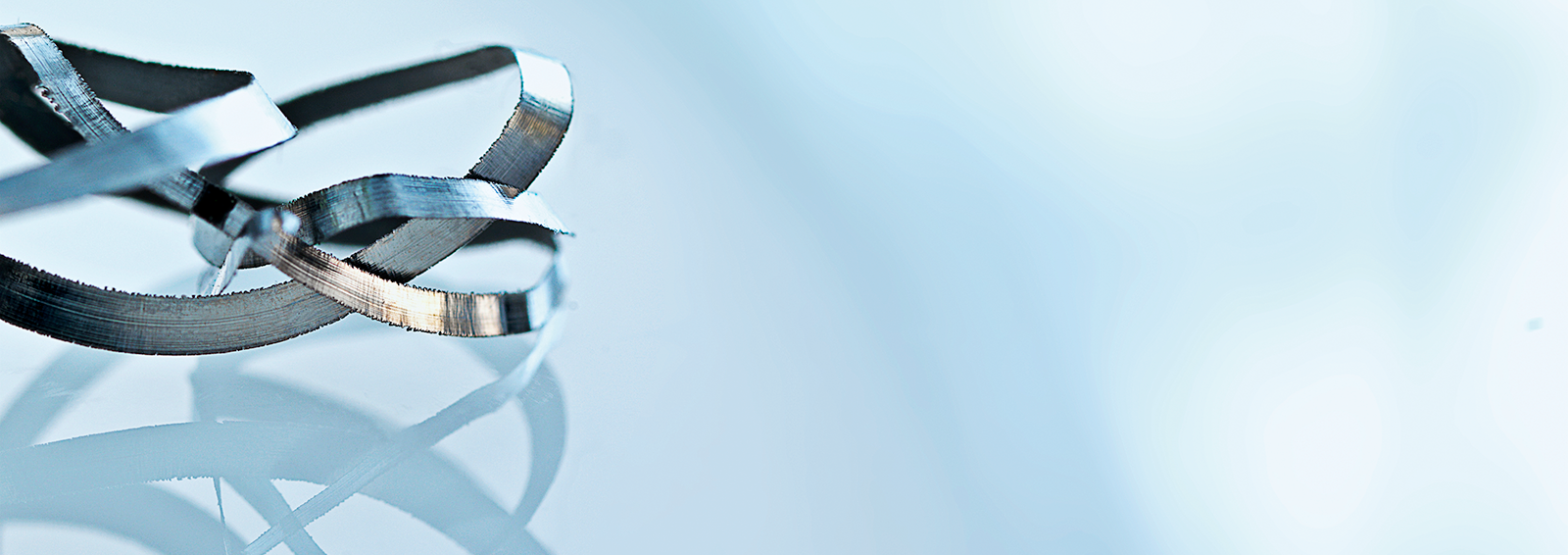

multidec®-WHIRLING serves you to significantly increase productivity in the production of threads. In contrast to conventional thread turning, which requires several cutting passes, thread whirling with multidec®-WHIRLING completes a thread without burrs in just one pass. By using up to 12 cutting edges, you can greatly reduce the machining time and save considerable costs. For optimal use, UTILIS offers different machine-specific variants with different flight circles and lengths.

The cutting edges of multidec®-WHIRLING are based on those of multidec®-CUT. This grooving/turning tool system is ideal for sliding headstock automatic lathes with a maximum bar capacity of Ø 10 mm. The inserts have two cutting edges, which are screwed onto the holders with a repeat accuracy of < 0.01 mm are screwed onto the holders.

Features and benefits:

-

Up to 12 inserts increase productivity significantly and reduce vibrations considerably

-

Low concentricity errors and high changeover accuracy of the plate < ±0.005 mm guarantee high quality threads

-

Quick and easy change of the whirling tool reduces the set-up time

-

Burr-free thread profiles reduce post-treatment

-

Use of UTILIS standard blanks enables short delivery times with coatings optimally matched to the material to be machined

-

Whirling heads with different flight circles as well as for multi-start threads available

Lirim SALJIHI

Lirim SALJIHI